Contract Manufacturing

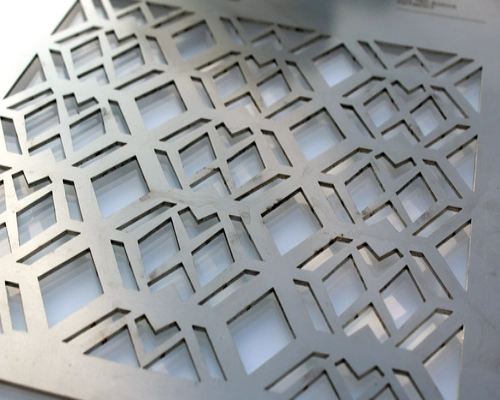

Laser Cutting Services

We have been focusing on precision metal laser cutting service for 20 years, on-demand customized laser cut parts in many metal materials, Rapid Prototyping, no minimum order quantity, real factory quotation, professional technical support, one-stop sheet metal fabrication service.

Laser Cutting Services

Formtechsolution has been specializing in laser cutting metal parts for 20 years, providing precise and fast laser cutting services to a wide range of industries, with hundreds of materials to choose from and no minimum order quantities to meet all your needs and financial pressures.

With our 10.000KW and 6.000KW industrial grade laser cutting machines, we can accurately cut stainless steel, aluminum, copper alloys, titanium alloys, carbon steel sheets, wood panels, engineered plastic panels, and more.

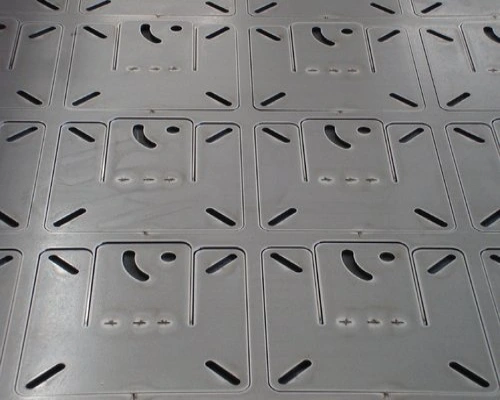

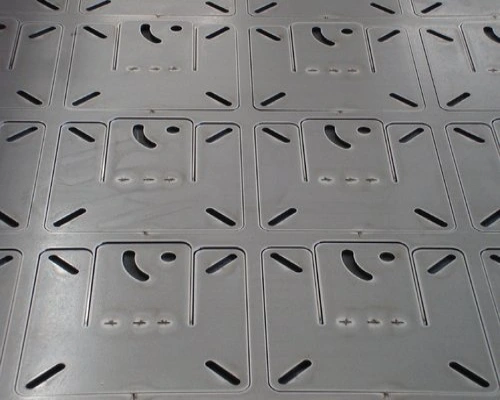

We are a real sheet metal manufacturer, providing one-stop customized sheet metal parts service to industry leaders from all over the world, offering cost-effective factory quotes that are affordable for individuals or small to medium-sized companies.

-

Dimensional accuracy: ±0.10mm

-

Laser incision: 0.2mm

-

Material thickness: ±0.05mm- 35mm

-

Maximum stroke: 1220mm*6000mm

Rapid Prototype Turnaround

Committed to exceeding expectations for quality and rapid turnaround, and meeting high-quality sheet metal parts.

On-Demand Sheet Metal

Whether it is rapid prototyping & large-volume manufacturing, we will implement it according to customer needs and standards.

Real Fabricators Price

Integrate product design, bending, stamping, cutting, surface treatment, etc. to provide a series of manufacturing solutions.

Optional laser cutting materials

Formtechsolution offers a robust stockpile of materials to help your products can get up and running with a quick turnaround.

Within an hour, the metal material is ready for the sheet metal bending process.

Aluminum alloy laser cutting

5052-H32 / 6061-T6 / 6063-T5 / 7075 etc.

Stainless steel laser cutting

201 / 301 / 304 / 316

Carbon steel laser cutting

mild steel / galvanized steel / alloy steel

Copper laser cutting

Bronze / White Copper / Pure Copper / Brass

Fast turnaround laser cutting services

Efficient laser cutting services allow us to maintain our competitive manufacturing capabilities, maintain a high level and quality of delivery, and offer a 100% money back guarantee on all parts. You will benefit here.

-

Professional English speaking sales team.

-

A full range of after-sales protection.

-

Keep your part design confidential (signed NDA document.)

-

Experienced team of engineers to provide manufacturability analysis.

Full range of technical support

Don’t have a professional design files?

If you don’t already have a professional designer to create professional part design files for you, then we can help you with this task.

You can tell me your inspirations and ideas or make a sketch and we can turn them into real products.

We have a team of professional engineers who will analyze your design, suggest material selection, and final production and assembly.

One-stop technical support service can make your work easy and convenient.

Why Choose Formtechsolution

At Formtechsolution, we will use the most suitable laser cutting equipment according to the material and design shape, including some special laser machines (1000Kw micro cutting machine, five-axis laser cutting machine, 20.000kw super large laser cutting machine) and other external suppliers resource. Ensure to provide customers with the smallest error laser cutting service.

-

0.05-6mm thickness stainless steel plate ±0.1mm

-

6mm-10mm thickness stainless steel plate ±0.2mm

-

10mm-25mm thickness stainless steel plate ±0.35mm

-

25mm-35mm thickness stainless steel plate ±0.5mm

Full range of on-demand manufacturing

With our extensive experience in custom sheet metal fabrication and our advanced equipment.

We can handle precision sheet metal fabrication projects for any industry.

Sheet Metal Laser Cutting

Sheet Metal Bending

Metal Welding Fabrication

Countersunk and Threaded

Hardware Insertion

Powder Coatings

Anodic Oxidation

Electroplated

Laser Engraving / Logo Printing

Why Choose

Laser Cutting Advantages

Laser cutting has a multi-purpose cutting process. It is very effective in prototypes and parts that need to be cut quickly. Laser cutting has great advantages in terms of precision and high efficiency that traditional metal cutting cannot meet.

-

High efficiency

-

Low cost

-

Accurate size

-

Save material

-

Automated manufacturing

-

Mass cutting

-

Wide range of materials

-

Suitable for complex designs

-

Does not change material properties

An Overview for :

What is laser cutting processing

Laser cutting is one of the efficient and economical cutting processes. The surface of the material is heated by a laser beam to penetrate the material for cutting. Laser cutting is similar to a cnc machine, with a digital process that accurately cuts out precise and complex shapes.

This is a very convenient way of cutting. The product we designed can be reached within ten minutes. Usually, as the initial process of sheet metal bending and sheet metal prototype, we quickly put the cut into the mold to facilitate forming .